Technical features of DF-F compressor:

1) The structure of the machine body adopts the structure of an integral fully enclosed rib structure, which is characterized by a large number of main bearing stalls, compact arrangement and strong rigidity;

2) The single crank single row and short crank radius structure are adopted for the crankshaft. The bearing capacity of the crankshaft is significantly improved, the transmission torque is enhanced and the matching is flexible, allowing the compressor to run at high speed. In addition, the characteristics of high speed and small turning radius also reduce the starting torque of the unit. The bottom of each crank arm can be equipped with a variety of weight series of standard counterweights. The coupling end is equipped with a flywheel to reduce the inertia moment of the unit. The connection between the crankshaft and the driver is positioned by using the flange inner seam and tightened hydraulically, avoiding the installation difficulties caused by the use of reamed bolts and tightening by experience for domestic units.

3) The connecting rod basically adopts die forging structure, and its main structural characteristics are reflected in its large and small head pads. The big head pad is an upper and lower half structure, and the clearance can be adjusted by padding; There is a spiral oil groove in the small head pad, which is easy to establish an oil film, so that the crosshead pin can be well lubricated. Main bearing bush, connecting rod big and small head bush and crosshead sliding shoe are made of aluminum magnesium alloy.

4) The cylinder can be lubricated with or without oil. The cylinder materials include cast iron, ductile iron, steel or forged steel.

5) The piston is made of cast iron, forged steel, aluminum alloy and other materials; The piston rod is made of alloy steel and stainless steel to meet various applications. Except that the piston rod threads are all pressure rolled, the main structural features of the piston are shown in the piston support rings and piston rings made of self-lubricating organic materials in various structural forms. The running end face and vertical running end face of the support ring are equipped with different numbers of inclined guide grooves or pressure guiding holes, so that the support ring will not generate back pressure like the piston ring, and the support ring will be driven to rotate freely by the air pressure during operation, which not only ensures the support function, but also makes it wear evenly, and significantly improves its service life.

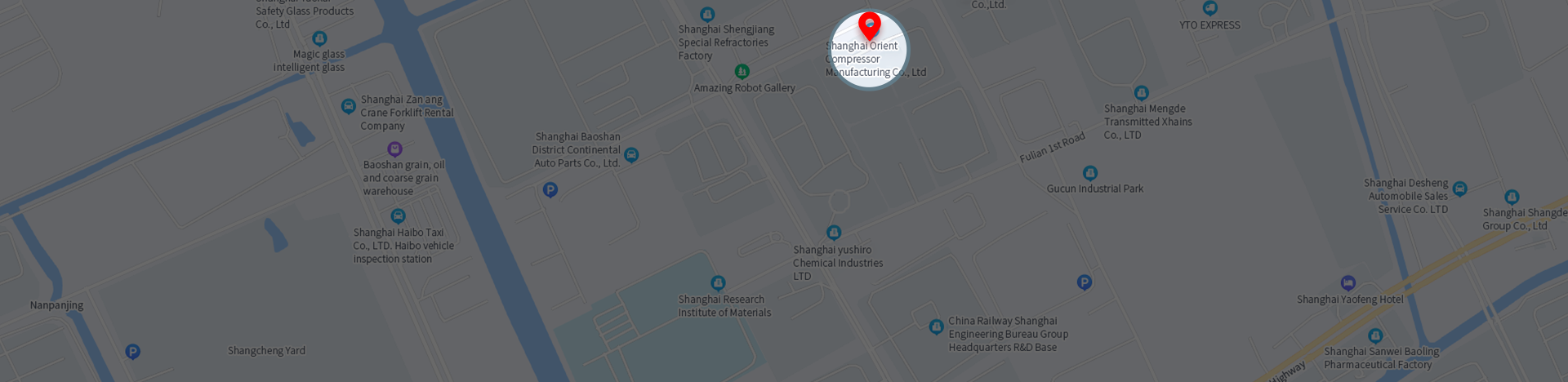

ADDRESS:No. 318, Fulian Second Road, Gucun Industrial Park, Baoshan District, Shanghai

ADDRESS:No. 318, Fulian Second Road, Gucun Industrial Park, Baoshan District, Shanghai

PHONE:+86-21-36043952

PHONE:+86-21-36043952

WEBSITE:www.orient-compressor.com

WEBSITE:www.orient-compressor.com

EMAIL:sales@orient-compressor.com

EMAIL:sales@orient-compressor.com