Technical features of DF-C compressor:

1)The fuselage is "U" shaped and flat bottomed, with a bolted fuselage top cover for easy access to the main bearing and crank pin bearing. The middle body and crosshead slideway are integrated with the fuselage, and the fuselage is supported by strong grid shaped ribs, which can ensure the coaxiality of the bearing holes.

2)The crankshaft is a fixed crank type crankshaft with a main bearing between each pair of cranks. The crankshaft is made of forged steel and is stress relieved and heat treated. The main journals and crank pins of all gears are finely ground and polished. An oil passage is drilled in the crankshaft from the main bearing journal to the adjacent crank pin.

3)The main bearing bush, connecting rod big and small head bush and crosshead slipper are made of aluminum magnesium alloy.

4)The cylinder can be lubricated with or without oil. The cylinder materials include ductile iron, cast steel, welded carbon steel or stainless steel and forged steel.

5)The piston is made of cast iron, forged steel, aluminum alloy and other materials; The piston rod is made of alloy steel and stainless steel to meet various applications. The yield strength of all piston rods shall be at least 517MPa. The piston rod can be high-frequency quenched, precipitation hardened or hot coated according to different requirements. The surface roughness of pressure packing and oil scraper ring area is 0.2 μ m~0.4 μ m。

6) Body lubricating mechanism: the oil enters the gear oil pump driven by the crankshaft from the body oil pool. The oil discharged from the oil pump passes through an external cooler and an external oil filter, and then returns to the main bearing oil collecting pipe, which is a pipe cast into the bottom of the machine body. The oil from the main bearing oil collecting pipe is delivered to each main bearing through the bore hole on the bearing pedestal, and flows through the passage in the crankshaft to the crank pin bearing. The coming and returning holes in the connecting rod send oil from the crank pin to the crosshead pin bushing at the small end of the connecting rod, then enter the crosshead pin, then enter both sides of the crosshead, and from here enter the crosshead sliding shoes at the top and bottom. After lubricating all parts, return to the oil pool and continue to circulate. The motor driven auxiliary oil pump is used to lubricate the bearing surface and pressurize the lubricating oil system before starting. In addition, the auxiliary oil pump is also used as a backup when the main oil pump fails.

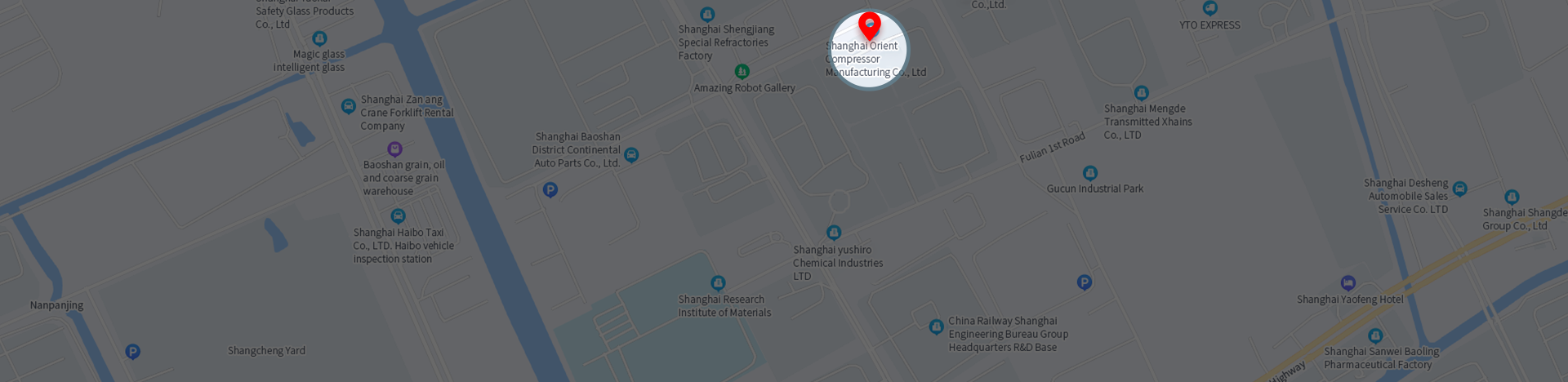

ADDRESS:No. 318, Fulian Second Road, Gucun Industrial Park, Baoshan District, Shanghai

ADDRESS:No. 318, Fulian Second Road, Gucun Industrial Park, Baoshan District, Shanghai

PHONE:+86-21-36043952

PHONE:+86-21-36043952

WEBSITE:www.orient-compressor.com

WEBSITE:www.orient-compressor.com

EMAIL:sales@orient-compressor.com

EMAIL:sales@orient-compressor.com