Technical features of DF-L compressor:

1) The structure of the machine body adopts the structure of an integral fully enclosed rib structure, which is characterized by a large number of main bearing stalls, compact arrangement and strong rigidity. The resin sand precision casting and CNC machine tool processing are adopted to ensure the concentricity of the main bearing and the perpendicularity of the sliding edge. The rigid connection flange disc with flywheel forged integrally at the shaft end is connected with the drive stage, with stable dynamic performance and high rigidity.

2) The crankshaft is an alloy steel forging with high tensile strength, which has been stress relieved and heat treated. The included angle of the crank is equally divided by 360 °, and the odd sequence of opposed structures can be designed. DF can have a design of one to ten cranks, which is not limited by the even number of cranks. The unbalanced force and moment on the foundation are smaller; Lower cost of foundation size; Motor current pulsation is reduced, power consumption is reduced, and power consumption is reduced.

3) DF-L unit adopts hydraulic tightening structure, which is different from the connection structure designed in China in that the hydraulic tightening puller is only used as a random tool and is not designed on the crosshead like the domestic structure. The main bearing bush and connecting rod big end bush are made of aluminum magnesium alloy; The crosshead is cast iron; Small head tiles are bronze.

4) The cylinder can be lubricated with or without oil. The cylinder materials include cast iron, ductile iron, steel or forged steel. The cylinder block is basically designed as a "through cylinder" structure. The air passages are arranged as upper inlet and lower outlet, equipped with replaceable dry cylinder liners. Large valve hole design, resistance coefficient is relatively small.

5) The piston is made of cast iron, forged steel, aluminum alloy and other materials; The piston rod is made of alloy steel and stainless steel to meet various applications. The piston rod thread is pressure rolled, and a variety of self-lubricating organic material piston support rings and piston rings are used. According to the different working environments, the support ring can be designed with components, whole structures, etc. The running end face and vertical running end face of the support ring are equipped with different numbers of inclined guide grooves or pressure guiding holes. During operation, the support ring is driven by air pressure to rotate freely, which not only ensures the support function, but also makes it wear evenly and improves its service life significantly.

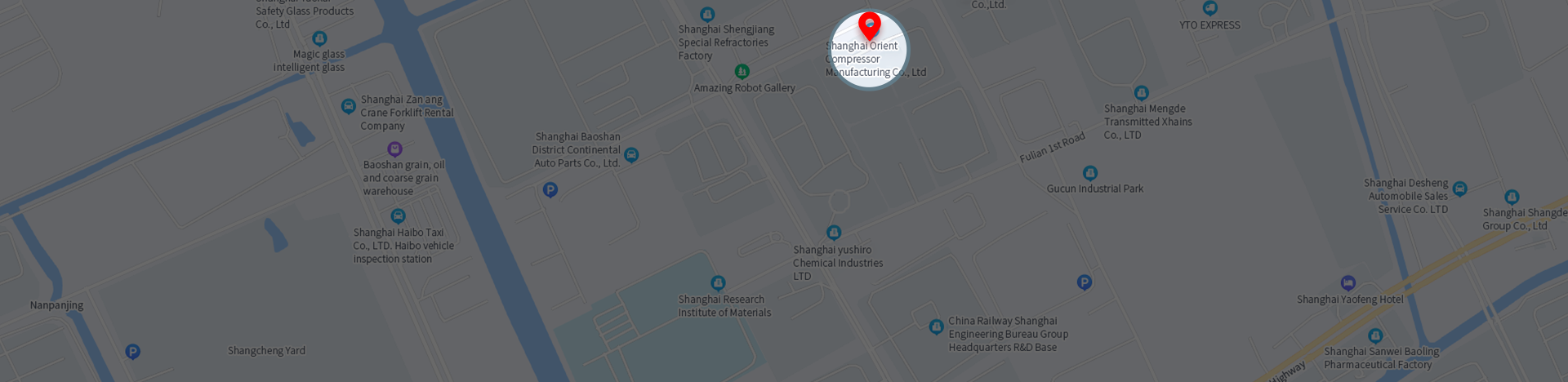

ADDRESS:No. 318, Fulian Second Road, Gucun Industrial Park, Baoshan District, Shanghai

ADDRESS:No. 318, Fulian Second Road, Gucun Industrial Park, Baoshan District, Shanghai

PHONE:+86-21-36043952

PHONE:+86-21-36043952

WEBSITE:www.orient-compressor.com

WEBSITE:www.orient-compressor.com

EMAIL:sales@orient-compressor.com

EMAIL:sales@orient-compressor.com