1. The product series is neat and covers a wider range

The application of the eight piston force grade series of DF products and the odd series of opposed balance technology has created a wider coverage and more flexible application of DF compressor products.

2. High dynamic balance

The single crank single row design makes the included angle of the crankshaft evenly distributed on the circumference. The broken arm and high rigidity structure make the overall dynamic performance of the fuselage easy to solve.

3. Low unit operation noise

The application of synthetic materials in the whole process and the high balanced power performance of the unit provide guarantee for reducing the noise of the unit.

4. Complete programmed design

The design of DF product parts is based on the development of perfect design software, comprehensive and accurate design, the whole process from product parameter login to part drawing output, and computerized design technology to ensure product performance.

5. Modular development to ensure design speed

DF's complete enterprise standardization degree and rich basic parts library make the product variant fast and convenient.

6. Few vulnerable parts, long service life

The application of high-tech materials and the structural design of parts have improved the service environment of vulnerable parts and made them more suitable for working conditions.

7. Low energy consumption

The structural characteristics of DF compressor and the application of special bearing bush technology, air valve technology and special material technology of the unit have greatly improved the transmission efficiency, friction loss and airflow resistance loss of the unit, and significantly reduced the power consumption of the unit.

8. High technical accuracy and low maintenance and operation requirements

"DF" compressor has strict technical basis and specifications from design, manufacturing to installation, and has a strict quality assurance system. The size of its key parts is to avoid human error as much as possible. For example, the processing of the main shaft support of the machine body, the processing of the connecting rod bearing bush hole, etc. are all completed by the CNC machine tool. The pretightening of each bolt of the unit is controlled by a force measuring wrench and hydraulic tightening tools, It fully reflects the scientific nature of unit manufacturing and installation; In addition, the complete set of units provides less and more convenient operation requirements for operators, which can basically realize unmanned on-site.

The integrally cast aluminum magnesium alloy bearing bush has the advantages of high strength, low friction coefficient and long service life. Under the condition of forced lubrication, the pressure bearing capacity of the whole machine is five times that of Babbitt alloy bearing bush, and the service life is more than three times that of Babbitt alloy bearing bush. Its special material performance can provide reliable operation guarantee for the crankshaft.

Fuselage

DF body material is cast iron brand similar to HT207 in China. It adopts resin sand precision casting process and CNC machine tool processing to ensure concentricity of main bearing and perpendicularity to sliding edge. The frame type multi support structure is tightened with the support and pull rod bolts to control the torque, ensuring the rigidity of the fuselage. DF body is equipped with fuel tank and vent cap. The integrally forged rigid connection flange with flywheel at the shaft end is connected with the drive stage, which has the advantages of stable dynamic performance and high rigidity.

The DF connecting rod is made of high-strength die forged alloy steel and processed by a CNC machine tool. Its large head pad is of the upper and lower petal structure, which can be adjusted by adding shims. The small head pad has a spiral oil groove, which is easy to establish an oil film, so that the crosshead pin can be well lubricated; It has the anti fatigue performance more suitable for reciprocating compressor to resist pulse motion.

High strength alloy steel is used for torsion forging, single crank single row and short stroke structure; The sharp angle of the crank is evenly divided on 360 °, which is characterized by flexible matching, high bearing capacity, high speed and significantly reduced starting torque. The standard counterweight can be configured at the bottom of the crank as required to achieve better dynamic balance performance.

The transmission safety is guaranteed within the load range of each series. The detachable and adjustable sliding shoe structure is adopted. The sliding shoe is made of aluminum magnesium alloy. The "super nut" and hydraulic tightening connection enable the piston rod to be disassembled and assembled freely. Its centering adjustment pad can realize the fine adjustment of the piston centering without disassembly.

The connecting thread of piston rod is made by pressure rolling, the rod body is hardened by electric induction, and the materials are mostly 42CrMo, 38CrMoAl and 17-4PH. It has high fatigue strength and long wear life, and can bear various bad working conditions. The friction surface has high wear resistance after nitriding, solution or quenching and tempering treatment.

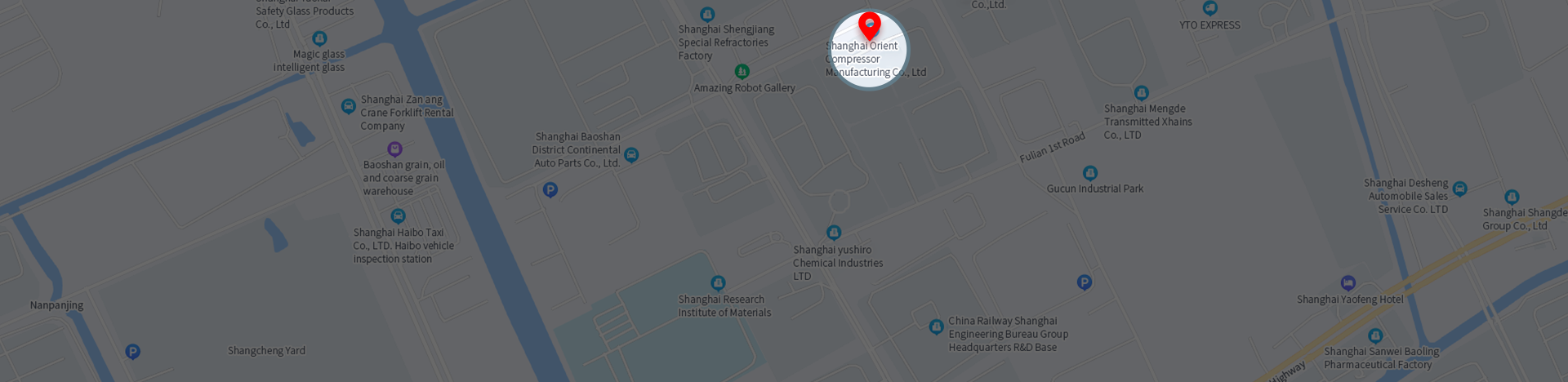

ADDRESS:No. 318, Fulian Second Road, Gucun Industrial Park, Baoshan District, Shanghai

ADDRESS:No. 318, Fulian Second Road, Gucun Industrial Park, Baoshan District, Shanghai

PHONE:+86-21-36043952

PHONE:+86-21-36043952

WEBSITE:www.orient-compressor.com

WEBSITE:www.orient-compressor.com

EMAIL:sales@orient-compressor.com

EMAIL:sales@orient-compressor.com